Precious Plastic: home recycling 2.0

Dave, you are a designer known in particular for the Phoneblocks, a prototype modular phone which has long interested Google. How did you get interested in plastic recycling?

I have always had a relatively minimalistic lifestyle, and I am not a compulsive consumer. That is why I often attempted to recycle the objects I do use. My job as a designer helps me to do that. However, it is not always easy, in particular for plastic objects made of a single piece. What really set me off on my current course was discovering open-air landfills and mountains of waste, much of it plastic, during a trip to Asia. That is the tragedy of the material; it does not rust, it does not rot, and it degrades very slowly. In some countries, those dumps are near rivers and the lightweight plastic waste flies away at the slightest breeze and ends up in the oceans.

|

I am well aware of the fact that plastics have changed our lives, and often for the better, but I am also aware of the fact that we must recycle them better and start considering them as a resource. They are too precious! |

Too many countries do not practice selective sorting due to a lack of resources, which is the case for certain countries in Asia, Africa, and South America, for instance. I love machines, and upon returning from Asia, I set out to design a device that was easy to use and manufacture so that it could be accessible to as many people as possible and could be used to recycle end-of-life plastics at home.

|

My wife came across a video in which Dave explained how to build a plastic recycling machine. She asked me to build one for her because she wanted to design new objects using our own plastic waste. It got me thinking, and I realised that we too, in a rich country, had a problem with our end-of-life plastics. |

|

What is your role within Precious Plastic?

I make use of this “technology”. My wife and I have started our own business! We offer to build the machines because although the plans can be downloaded for free on the Internet, you need to have some DIY skills and the right tools, such as a welding station for instance. Since then, we have been selling turnkey machines, but above all machines that are custom-built depending on our customers’ needs. We have contracts all over the United States and we are getting increasingly more requests from around the world. To the extent possible, we recommend that those furthest away from us either build their machines themselves or seek out local help as that reduces our carbon footprint. The Precious Plastic community is constantly growing on all continents. It would be surprising if help could not be found in the local area.

|

Dave, can you tell us more about these machines?

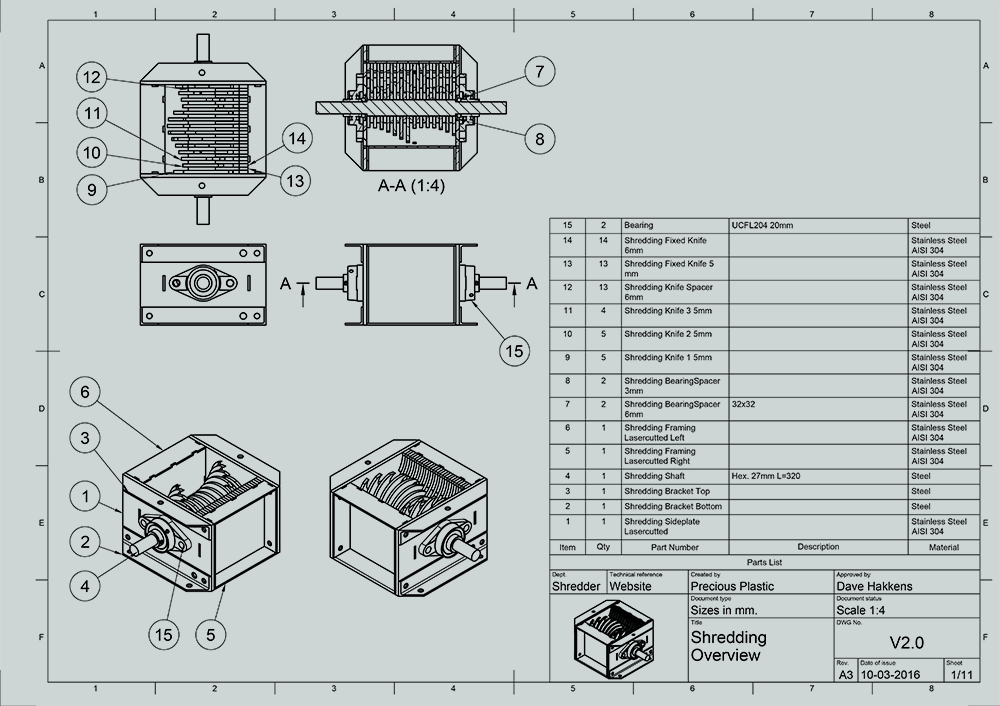

I wanted them to be very simple to enable anyone to build them. In fact, there are four of them. The first is used to grind the plastics little by little like a meat mincer. It consists of a receptacle in which the used objects are placed. They are then driven into a system of blades driven by an electric motor or by the force of the calf. This process creates chips or flakes, and that's where the other machines come in. The chips are heated and melted before being extruded or moulded in an injection or compression press. The last machine is an extruder with different dies that can produce poles of any diameter or wire for 3D printers.

I have imposed four main rules on myself when designing these different machines: they must be modular and therefore exclusively composed of elements that can be easily customised and replaced. The plans are open source so they are accessible to everyone for free on my website. The elements are basic to allow them to be manufactured anywhere in the world, including with recycled materials. Finally, they are easily "manufacturable" since I publish very detailed tutorials on my website.

Who are they intended for?When I started this project, I did not have a business model. I just wanted to contribute to the recycling of plastic objects, in my own way. The business model became clear as the project moved forward. Today, these machines can be found all over the world and many micro-businesses have been created, particularly in emerging countries. The Precious Plastic community has approximately 40,000 members who work either to promote the machine or to make objects and then sell them. I know that artists have also built the machines in order to create unusual works. In fact, they can be used to do almost anything, you just have to have a little imagination: cups, lamps, trays, boxes, toys, and more. I am very happy with the result, but the users are free to use the machines as they please. What matters is that they make it easier to recycle plastics and if that contributes to the economy of a village, a region or even a state, that is all the better! |

|

What are your plans for the future?

Dave: I would like there to be machines throughout the world one day, so that everyone can recycle their plastics to make new, useful objects. We are raising funds to send free starter kits to those who would like to start a business in the poorest countries.

|

Jacob: in the short term, we would also like to see more machines around the world. In the longer term, I would like for people to realise that plastic waste is a resource that can be exploited. We recently approached a global financial company to set up a business for renting out the machines around the world. Initial feedback has been promising. |

|