Polymers: a colourful history

Fifties and sixties: plastics are the height of cool

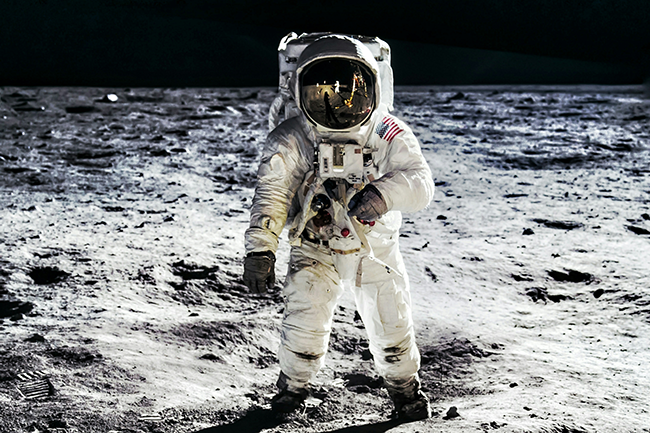

At the end of the 1940s, Europe was undergoing reconstruction and restrictions were still in force. On the other side of the Atlantic, less affected economically, society was evolving more rapidly and gaining in modernity. This was the American way of life and the plastics industry, now mature, was to make a major contribution to its development. Engineers continued their research, aided by improvements in catalysis techniques and industrial processes. Although these decades were less fruitful than the previous one, they were nevertheless associated with the development of new polymers and, above all, with their production in large quantities. At the same time, mass consumption appeared. Demand exploded and the industry responded by developing another star in the making: polypropylene. Polypropylene earned the Italian Giulio Natta and the German Karl Ziegler a Nobel Prize in chemistry. Its ease of moulding, its resistance to wear, impact and chemical aggression and its low cost made it a favourite with processors: its range of applications is virtually unlimited, from packaging, toys, car and aircraft parts, to films, banknotes and concrete additives. Its only drawback is that it becomes brittle in extreme cold. PET (polyethylene terephthalate), which in its textile version would be called polyester, soon followed. This was a fibre which, according to a famous slogan, "will also free the housewife" because clothes made of this new material did not need to be ironed. It was not until the 1970s that PET was used to make bottles that were much lighter than those made of PVC and much less fragile than those made of glass. Polycarbonate and ABS were also commercialised in the 1950s. Both are ultra-strong polymers, the first of which was used in the design of the helmets of the astronauts in the Apollo programme and accompanied Neil Armstrong's first steps on the moon! As for the other, it is, as one example among many, inseparable from the success of Lego bricks. It would also be inappropriate not to mention melamine-formaldehyde, better known as formica, an emblematic material of the 1950s. It was used in modern kitchens and would be replaced by ABS 20 years later, or by high density polyethylene and of course polystyrene, both of which would find numerous applications in the packaging sector.

|

The Apollo astronauts' spacesuit is a condensation of polymers. Among them, the very resistant polycarbonate used to make the helmet. |

Chic plastics

In just one decade, the traditional industries of wood, paper and glass gave way to plastics. Flexible, lightweight, colourful and easy to use, polymers became everyday items and entered homes at all layers of the social strata. They became so essential that they inspired the greatest designers of the time. Some of their creations have become cult objects that are now sold at a premium. Danish designer Verner Panton made a name for himself worldwide by creating a brightly coloured one-piece chair made of fibreglass-reinforced polyester. He said: "Thanks to technical progress and new plastic materials, designers can now make objects that previously could only exist in their dreams. Piero Gatti, Cesare Paolini and Franco Teodoro, three Italian designers, reinvented the armchair by creating the Sacco, the world's best-known pouffe made of a PVC shell filled with polystyrene balls. Without polymers, and in particular PMMA, would the Italian company Kartell have been able to bring design within the reach of (almost) everyone and become so famous? When we think of these decades, we rightly speak of the plastic years, as polymers were proudly displayed by the most modern people. However, relegating them to being good only for consumer goods is giving them short thrift. Research is still ongoing and the industry is endlessly searching for new polymers for much more high-tech sectors such as electronics, aeronautics and medicine.

Polyester helped Danish designer Verner Panton become an internationally renowned star with his namesake chair. |

Oil crisis, polymers find a new destiny

1976 was a key date for plastics, which for the first time in their short history became the most widely used materials in the world. However, the 1973 oil crisis and the accompanying price hikes could have caused the vast majority of oil-based polymers to fall out of favour. To cope with a possible drop in demand, the industry sought to develop so-called high-performance materials with high technical added value. Plastics became more sophisticated, their new properties making them incomparable materials to definitively establish their superiority over metals, glass and ceramics, which were also continuing to develop.

This led to the development of polyacetals, the best known of which is POM (polyoxymethylene), a rigid, hard polymer with very high resistance to creep and traction. It successfully replaced metals in many sectors linked to the mechanical construction of parts that require great stability such as pinions, bearing wheels, rotors, etc. Its low weight is a considerable advantage over metal, particularly for the automotive and watchmaking industries.

Another high-performance polymer is PEEK (polyetheretherketone), marketed in the late 1970s by the British company ICI. A particularly expensive polymer, it won over the aeronautical industry in particular for its characteristics such as high flexural and tensile strength, even in extreme conditions, and above all for its resistance to temperatures exceeding 250°. These properties are also found in certain metals, but they weigh much more. These new polymers are now used in many sectors, such as the automotive and aeronautical industries, where they are used to put transport vehicles on a diet in order to reduce consumption, and the medical sector, where they are used in the form of prostheses, stents and even artificial hearts.

Of course, the family of polymers is much more extensive than these few examples. We have only mentioned the best-known ones here.

High performance plastics have many applications in the medical field, particularly in prostheses.. |

The chemical industry is currently accelerating its research and is looking towards bioplastics such as PLA, PHAs which appeared in the 1990s, and towards both mechanical and chemical recycling solutions. But above all, together with processors and public authorities, it is adopting the eco-design reflex, to envisage a different way of designing objects to consume differently. The industry is well aware of the present and future challenges and each time, polymers have shown resilience to adapt to their environment. One thing is certain, their story is far from over.

More information:

https://plastics-themag.com/Converting-the-old-into-a-virgin-plastic

https://plastics-themag.com/Bioplastics-take-root

https://plastics-themag.com/We-have-barely-begun-to-explore-the-world-of-bioplastics

https://plastics-themag.com/Savings-in-ressources