Seabird, a lifeline for the fishing industry and marine life

What is Seabird's vocation ?

Seabird is more than just a manufacturer, it is a design firm created in 2011 by Marie Chauvel, a plastics engineer, for the purpose of offering solutions, aimed at considerably reducing the impact of conventional plastics used in the marine environment and port activities. More concretely, our start-up was created for the purpose of selling an innovative product: a phosphorescent bird scaring line for the fishing industry. It was in fact this invention which served as inspiration for our company's name.

What is the device's purpose ?

In the absence of safety measures, fishing can have a considerable impact on seabird populations. Longliners, for instance, submerge long trolling lines that contain up to 2,500 baited hooks. In the absence of protection, the birds that try and catch the bait get caught on the hooks and drown. They also often get trapped in the trawlers' gill nets.

In the absence of safety measures, fishing can have a considerable impact on seabird populations. Longliners, for instance, submerge long trolling lines that contain up to 2,500 baited hooks. In the absence of protection, the birds that try and catch the bait get caught on the hooks and drown. They also often get trapped in the trawlers' gill nets.

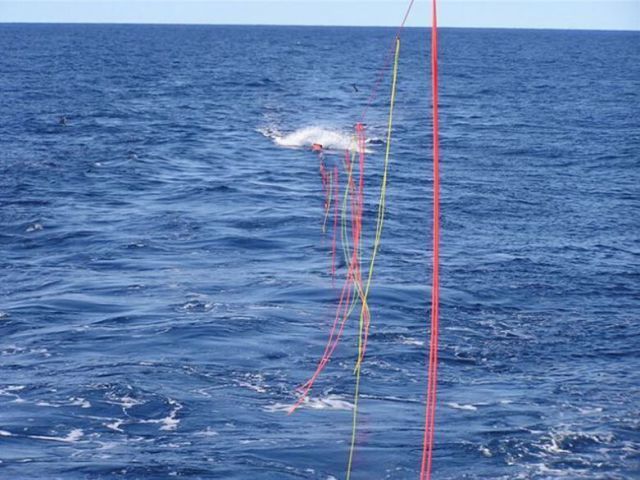

However, fishermen have long known that the presence of phosphorescent plankton on the surface of the sea keeps seabirds away from schools of fish. Taking inspiration from this phenomenon, we developed a phosphorescent line which, when stretched from the top of the mast to the nets, keeps birds away from the nets thus making it easier for the fishermen to pull in the nets. Two version of this line are made from two types of polymer modified with a luminescent pigment. One is biodegradable, and is the first bio-sourced resin developed by Seabird. The other is a conventional polyethylene.

How is biodegradability useful for this type of fishing gear ?

In this particular case, it is an additional function that we have added to our device whose main aim is that of protecting seabirds. However, biodegradability is also the main characteristic that Seabird is aiming to promote in other projects.

In this particular case, it is an additional function that we have added to our device whose main aim is that of protecting seabirds. However, biodegradability is also the main characteristic that Seabird is aiming to promote in other projects.

The best known of these is our Biofima monofilament. It is a 40% bio-sourced synthetic filament with a controlled lifetime. Its mechanical properties are practically comparable to those of conventional filaments, polyester and polyamide, used to manufacture fishing lines and nets. Its main purpose is that of ensuring slow biodegradation of the material in the marine environment and thus total elimination, in the long term, of the fishing lines and nets lost at sea.

Is this degradation not in opposition to fishermen's expectations ?

No, because although our polymer is biodegradable, it provides them with the same mechanical properties required for their activity, for a period of 2 to 5 years, depending on the monofilament diameter, which is far beyond the normal useful lifetime of their current lines and nets.

So how does it benefit marine life ?

Contrary to what you may imagine, the benefits are considerable. Consider that a conventional net lost at sea would take a considerable time to break down to the point that it would no longer trap marine life. Our Biofima filament brings down the lifetime from fifteen to thirty years. In addition, its biodegradation implies a complete assimilation into the marine biotope and not micro-fragmentation. The process is therefore that of true biodegradation, and is therefore in no way similar to that of oxo -biodegradable plastics.

Contrary to what you may imagine, the benefits are considerable. Consider that a conventional net lost at sea would take a considerable time to break down to the point that it would no longer trap marine life. Our Biofima filament brings down the lifetime from fifteen to thirty years. In addition, its biodegradation implies a complete assimilation into the marine biotope and not micro-fragmentation. The process is therefore that of true biodegradation, and is therefore in no way similar to that of oxo -biodegradable plastics.

What are the upcoming developments in your work for the maritime industry ?

We are developing a new type of fish bin, manufactured using a 62% biobased compound adapted to injection moulding processes. The aim is to provide fishermen and fishmongers with biodegradable and industrially compostable plastic fish bins. The biobased, connected and ergonomic bins will be designed to meet users' needs and constraints while anticipating changes in waste regulations.

We are developing a new type of fish bin, manufactured using a 62% biobased compound adapted to injection moulding processes. The aim is to provide fishermen and fishmongers with biodegradable and industrially compostable plastic fish bins. The biobased, connected and ergonomic bins will be designed to meet users' needs and constraints while anticipating changes in waste regulations.

What advances will Seabac contribute in this area ?

It aims to correct the unsatisfactory management of the storage bins used on board fishing vessels and for selling fishery products. The bins, most of which are made from high density polyethylene, are subjected to heavy use. They are quickly rendered unusable because of successive impacts and changes in temperature. They are also misused or stolen, if they haven't been lost at sea first. In any case, the ecological consequences are considerable: pollution of the marine environment when they are lost at sea, and a waste management in the absence of a suitable recycling system on land.

Managing the bins actually generates significant operating costs. Improving their management is therefore a significant challenge for port stakeholders. This situation is all the more problematic as, in a few years' time, fishermen will be obligated to land the by-catch, thus increasing the number of bins on fishing vessels.

Your project's success therefore depends on the ability to recycle the bins ?

At the end of their life, the bins will be industrially composted: the creation of a specific recycling system is obviously indispensable. This is why it is crucial to raise awareness among fishermen and fishmongers as regards the circular economy, before involving them in the creation and functioning of a dedicated recycling system. We will most likely need to improve the Seabac concept as regards traceability.

At the end of their life, the bins will be industrially composted: the creation of a specific recycling system is obviously indispensable. This is why it is crucial to raise awareness among fishermen and fishmongers as regards the circular economy, before involving them in the creation and functioning of a dedicated recycling system. We will most likely need to improve the Seabac concept as regards traceability.

What are some other possible applications for your polymer ?

In the field of fisheries and aquaculture, it is easy to imagine our resins being used to manufacture most of the equipment intended for fisheries and aquaculture: lines and nets, or rigid equipment such as fish pots.

In the field of fisheries and aquaculture, it is easy to imagine our resins being used to manufacture most of the equipment intended for fisheries and aquaculture: lines and nets, or rigid equipment such as fish pots.