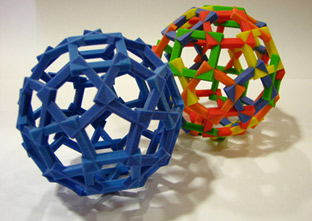

A local 3D print shop around the corner

How many members does your network have worldwide today ?

We are a bit surprised by how much success our idea has had. Within a matter of months, 3D Hubs has become the world's biggest 3D printer network. It currently offers 5000 registered users access to 1400 print sites or shops. Around 10 new print sites are joining the network every day. About two-thirds are located in Europe and one in five in North America.

Are they personal or professional sign-ups ?

Since being formed, the 3D Hubs platform has attracted mainly desktop printer owners. That’s still the case, but in recent months we have seen an unexpected growth in sign-ups by professional printer owners. That might be due to our rising popularity in America. I don’t know.

Since being formed, the 3D Hubs platform has attracted mainly desktop printer owners. That’s still the case, but in recent months we have seen an unexpected growth in sign-ups by professional printer owners. That might be due to our rising popularity in America. I don’t know.

As to why, their culture leads me to believe that most of our network members tend to be more professional 3D printers. In fact, more than a quarter would like to make more use of their printer, so they are happy to find new opportunities through us. 3D printing services are a paying proposition and that’s a strong motivation, sure, but not the only one. Another good thing about these transactions also stems from the fact that 3D source file sharing is a big stimulus to creativity.

Where do plastics come into the development of 3D printing ?

Like it or not, the range of materials compatible with personal 3D printers is still limited as yet. I believe that the development of suitable new polymers will be decisive in consolidating the success of the market.

Like it or not, the range of materials compatible with personal 3D printers is still limited as yet. I believe that the development of suitable new polymers will be decisive in consolidating the success of the market.

The most popular plastics are ABS and PLA, but the demand for printing with materials like nylon, wood composites and flexible polymers like FlexPLA filaments shows the need for diversification.

Have plastics producers grasped the importance of this technology and what users of 3D printers want ?

My fear is that they are not seeing the potential of what is happening and user expectations, particularly the many opportunities for testing out new materials opened up by the development of desktop 3D printers. I think this is what makes the concept of service sharing offered by 3D Hubs even more interesting, because as yet there is no such thing as a versatile 3D printer, i.e., that can handle the different materials and precision or dimension criteria wanted here and there. So you may own the most high-powered 3D printer going, but you might still need another model.

What is the most outstanding project that Hubs 3D has contributed to in the past year ?

Looking at the many projects carried through as opportunities and leads arise, what surprises is the wide range of situations that networked 3D printing can deal with. Let me give you a recent for-instance: one of our members couldn’t find a spare part to repair the roof of his Saab convertible. A new roof would have cost at least €400 to €500. Finally, he managed to fix it for €12 in just 24 hours by scanning the defective part and printing it in 3D at one of the hubs where he lives.

Looking at the many projects carried through as opportunities and leads arise, what surprises is the wide range of situations that networked 3D printing can deal with. Let me give you a recent for-instance: one of our members couldn’t find a spare part to repair the roof of his Saab convertible. A new roof would have cost at least €400 to €500. Finally, he managed to fix it for €12 in just 24 hours by scanning the defective part and printing it in 3D at one of the hubs where he lives.

How do you see the future of your business ? Are you planning to diversify ?

Our long-term goal is maximising people’s local access to 3D printing worldwide. But we don’t see the development of this technology as being based just on prototyping or modelling - or even the creation of gadgets or personalised gifts. Some of the more frivolous current uses aside, 3D printing is already providing a serious alternative to mass production. Some of our members are already using our 3D printing network to repair items rather than throw them away.

Our long-term goal is maximising people’s local access to 3D printing worldwide. But we don’t see the development of this technology as being based just on prototyping or modelling - or even the creation of gadgets or personalised gifts. Some of the more frivolous current uses aside, 3D printing is already providing a serious alternative to mass production. Some of our members are already using our 3D printing network to repair items rather than throw them away.

This new culture of localised production and consumption can help reduce waste, shipping times and transport pollution. What’s to stop it enabling big-name brands or retail chains from localising their after-sales service in the future?