Plastics, indoor champions in all disciplines

Elasticity is the key to success

The oldest natural indoor sport flooring, linoleum, has been the standard since the mid-19th Century. Invented by Frederick Walton, this polymer composed of cork, jute, resin and linseed oil is 100% natural. Lino comprises a single layer only, which avoids the delamination risk of polymer laminates, giving it better load-bearing properties.

The 1970s saw the development of new polyurethane (PUR) and especially thermoplastic polyurethane (TPU) synthetic floorings.

Their wide colour palette and versatility means that these flexible point-elastic floors have largely replaced area-elastic floors like parquet, thus eliminating the need for multiple sports facilities!

Their wide colour palette and versatility means that these flexible point-elastic floors have largely replaced area-elastic floors like parquet, thus eliminating the need for multiple sports facilities!

These resilient floorings are suited for all disciplines and can even be used as an evening reception venue that won’t suffer under high-heeled shoes!

Only the International Basketball Federation is holding out against point-elastic surfaces and demanding hardwood floors, albeit with a polymeric coating.

Fewer sores in gyms and dojos

Obsolete and dilapidated sports halls are pretty much a thing of the past. Nowadays, sports buildings are basically a shell suitable for re-purposing. The new interchangeable sports surfaces can be switched around to suit your needs and wants. Fastening systems vary widely, too: interlocking for flush-fitting gym mats or even Velcro strips!

Obsolete and dilapidated sports halls are pretty much a thing of the past. Nowadays, sports buildings are basically a shell suitable for re-purposing. The new interchangeable sports surfaces can be switched around to suit your needs and wants. Fastening systems vary widely, too: interlocking for flush-fitting gym mats or even Velcro strips!

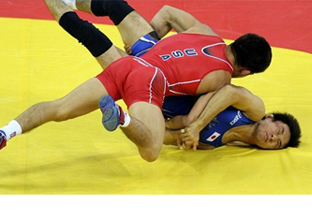

When it comes to martial arts, be it taekwondo, karate or judo, PVC-coated polyethylene or polyurethane foam tatami absorb all shocks and falls. New anti-slip finishes help minimise accidents even when climbing or wrestling!

But comfort and safety requirements are not the only important innovations. The addition of colloidal silver means that dojos are no longer plagued by foot odour!

This additive for gym mats is a boon to allergy-sufferers by also inhibiting the growth of many viruses, bacteria and fungi!

"Green" mats win on all fronts

Indoor sports are a golden opportunity for giving end-of-life polymer materials a longer life. Technical textiles used to cover open venues are easily reconverted into mats and tatami.

Indoor sports are a golden opportunity for giving end-of-life polymer materials a longer life. Technical textiles used to cover open venues are easily reconverted into mats and tatami.

The polyurethane foam (PUR) in car seats can also be given a new lease of life. Mixed with adhesive it is recycled into the protective layers of sports flooring. Given that a car yields, on average, eight kg of recyclable foam, there is great scope for the uses that recycled PUR foams can be put to.

Resins – keeping pools safe

The London Aquatics Centre is one of six permanent venues built for the Olympics and is part of London's urban renewal plan. So the project stakeholders have made sure it is kitted out with high-performance, sustainable indoor and outdoor facilities.

The London Aquatics Centre is one of six permanent venues built for the Olympics and is part of London's urban renewal plan. So the project stakeholders have made sure it is kitted out with high-performance, sustainable indoor and outdoor facilities.

The 425 running metres edging the competition, diving and training pools are covered with polyethylene duckboard flooring tiles, treated for corrosion and chemical-resistance.

New swimming pool materials now also receive antibacterial treatment. This has made them the first choice for swimming baths used by school parties which can be rife with verrucas!

For borders and basins and diving boards, resin, ethylene-propylene-diene monomer (EPDM) is still the best ally in the area, and sealing, to prevent slipping.

With this durable, waterproof and slip resistant elastomer, divers should be able to avoid the flop!