materials made for performance

"Faster, Higher, Stronger!"

The motto coined by the founder of the modern Olympics, Pierre de Coubertin, has lost none of its relevance in a world where records still regularly fall. Ever more sophisticated training methods obviously play a part.

But without advances in equipment and the often innovative use of composite materials, it's safe to say that athletes’ achievements would not be what they are today.

Composites take a bow

Racquet sports, cycling, fencing, water and combat sports ... featuring in the Summer Olympics is not the only thing these disciplines have in common. They all use equipment. And widely though it may differ, that equipment is all now very largely made of composites.

Racquet sports, cycling, fencing, water and combat sports ... featuring in the Summer Olympics is not the only thing these disciplines have in common. They all use equipment. And widely though it may differ, that equipment is all now very largely made of composites.

A composite is a material made from two or more different materials that remain separate and distinct. The newly-created material has properties that its constituent materials alone do not have. It comprises a structure of reinforcement materials that provide mechanical strength (carbon fibres, woven aramid) and a protective surround – the matrix material - which maintains the reinforcement materials in position. The matrix is usually a plastic: thermoplastic or thermosetting resin. Over 80% of sports equipment is made of these materials!

How come composites have taken over in this way? Simple, really. Their light weight and vibration-absorbing capacity make them the only materials that can deliver enhanced performance and comfort for sports equipment. These properties have revolutionized cycling and tennis in particular. Composites also offer the rigidity valued by archers and pole vaulters. Also, being hard-wearing, they greatly increase the dependability of sports equipment: mechanical strength and impact resistance for racquets, wet strength for water sports. Not to mention the impressive design flexibility offered by perfect moulding control.

How come composites have taken over in this way? Simple, really. Their light weight and vibration-absorbing capacity make them the only materials that can deliver enhanced performance and comfort for sports equipment. These properties have revolutionized cycling and tennis in particular. Composites also offer the rigidity valued by archers and pole vaulters. Also, being hard-wearing, they greatly increase the dependability of sports equipment: mechanical strength and impact resistance for racquets, wet strength for water sports. Not to mention the impressive design flexibility offered by perfect moulding control.

How the new materials have changed sports techniques

Take pole vaulting for example. Nowadays, top vaulters can clear 6 metres – the height of a two-storey building (!) – considered unfeasible in the early 1980s. Athletes readily admit that without these advances in equipment from using so-called special materials, their performances would not be what they are. Poles have gone through several distinct stages of development over a century - from bamboo to aluminium, then fibreglass and now a composite of fibreglass and carbon with epoxy-type synthetic resins. The result is a material that is both flexible and rigid enough to retain all the kinetic energy generated by the athlete enabling them to vault higher over the bar. And while it isn’t all down to the pole, vaulters have had to adjust their technique to adapt to these new materials so they can reach those unbeatable heights!

Power serves

Now you see it – now you don’t! As part of the crowd at a tennis match, basically you don’t see the ball! Watching it on TV is a better way to appreciate Federer’s forehand smash. Why? That’s right – the equipment and composite materials again! The first graphite racquets appeared in the 1980s. Carbon made them more rigid and, like vaulting poles, better transmitters of motion energy. The drawback was that their extreme rigidity started causing players serious “tennis elbow” problems.

Now you see it – now you don’t! As part of the crowd at a tennis match, basically you don’t see the ball! Watching it on TV is a better way to appreciate Federer’s forehand smash. Why? That’s right – the equipment and composite materials again! The first graphite racquets appeared in the 1980s. Carbon made them more rigid and, like vaulting poles, better transmitters of motion energy. The drawback was that their extreme rigidity started causing players serious “tennis elbow” problems.

Manufacturers have since solved this problem by incorporating shock absorbing materials in racquets. Substantially the same kind of innovation has also happened in other racquet sports like squash and badminton.

Speeding ?

Elite tennis players now shun carbon fibres in favour of more recently-developed carbon nanotubes which make racquets lighter and more rigid still, and especially more motion energy retentive. These new racquets are made of microscopic tubes with a diameter of about one nanometre (1 nm = 1 billionth of a metre), formed of one or more carbon sheets arranged in concentric cylinders. They are ten times more powerful than carbon fibre. Again, players have had to learn how to control these new "big guns". Service, smash, game, set and match!

Elite tennis players now shun carbon fibres in favour of more recently-developed carbon nanotubes which make racquets lighter and more rigid still, and especially more motion energy retentive. These new racquets are made of microscopic tubes with a diameter of about one nanometre (1 nm = 1 billionth of a metre), formed of one or more carbon sheets arranged in concentric cylinders. They are ten times more powerful than carbon fibre. Again, players have had to learn how to control these new "big guns". Service, smash, game, set and match!

The public, however, is less keen and misses the very long rallies of the 1970s.

That is something taken very seriously by the international federations and could put a damper on the development of still more efficient technologies ...

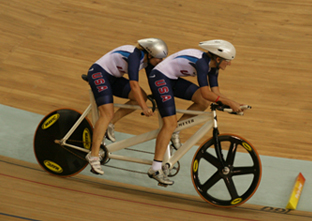

Cycling: carbon is the wheel thing

A power sport if there ever was one, cycling is certainly a prime illustration of how materials have moved on. In the first Tour de France in 1903, Maurice Garin averaged 25 kph on a bike weighing 20 kilos. A hundred years on, Lance Armstrong racked up an average 42 kph on a 7.7 kg machine (the minimum allowed by the International Cycling Union). Once again, carbon is the main component, with the fibres embedded in an epoxy resin. Carbon fibres are key for their strength, durability, lightness and malleability. And it is this latter quality that lets manufacturers choose when making a frame, fork, wheel rim or even a saddle, in which direction the fibres should go as that is what determines the properties of the final product – from highly rigid to highly flexible.

There are many possible combinations or "recipes" depending on the desired end result. Take the Ascend road bike designed by Delta 7 Sports, composed of carbon fibre/Kevlar woven into a lattice like a wicker basket. The heat-cured fibres have ten times the tensile stiffness and strength but much less weight than steel. What is also key to a bike is the ergonomics: finding the position that gives the cyclist the most power. So well are composite moulding techniques mastered that it is easy for manufacturers to turn out manufactured parts in the ideal shape.

There are many possible combinations or "recipes" depending on the desired end result. Take the Ascend road bike designed by Delta 7 Sports, composed of carbon fibre/Kevlar woven into a lattice like a wicker basket. The heat-cured fibres have ten times the tensile stiffness and strength but much less weight than steel. What is also key to a bike is the ergonomics: finding the position that gives the cyclist the most power. So well are composite moulding techniques mastered that it is easy for manufacturers to turn out manufactured parts in the ideal shape.

Competitive sailing gets leaner and meaner

Weight is the real constraint in any power sport. But solving that problem is not what drove the development of fibreglass/polyester boats in the early 1960s ... It was the height of the post-war economic boom years when many were discovering the joys of “messing about on the river”. Cabin cruisers still had wooden control consoles, and boat builders had a hard time keeping up with orders. A moulded fibreglass/polyester composite seemed to be the cheapest and easiest solution. It was a perfectly watertight material with everything going for it apart from the single fact of being almost as heavy as solid wood. But its low cost means it is still widely used for pleasure boats, canoes and surfboards.

Weight is the real constraint in any power sport. But solving that problem is not what drove the development of fibreglass/polyester boats in the early 1960s ... It was the height of the post-war economic boom years when many were discovering the joys of “messing about on the river”. Cabin cruisers still had wooden control consoles, and boat builders had a hard time keeping up with orders. A moulded fibreglass/polyester composite seemed to be the cheapest and easiest solution. It was a perfectly watertight material with everything going for it apart from the single fact of being almost as heavy as solid wood. But its low cost means it is still widely used for pleasure boats, canoes and surfboards.

The headway made by carbon in many sports started boat designers thinking: working with boat builders they came up with a sort of “garage-built” new type of carbon fibre hull specifically for elite-level competition.

The weight gain has added so much to powerboat speeds that they can now circle the world in forty-five days.

Boating: sail or wing ? It’s a wing-sail !

But the real revolution lies in the use of these so-called special fibres in textiles (sails and rigging). Nylon was already being used in sailmaking as early as the 1950s. On the plus side it was a very quick-drying material; the equal downside was that it quickly lost shape. That made it hard to get a performance-delivering sail area...

But the real revolution lies in the use of these so-called special fibres in textiles (sails and rigging). Nylon was already being used in sailmaking as early as the 1950s. On the plus side it was a very quick-drying material; the equal downside was that it quickly lost shape. That made it hard to get a performance-delivering sail area...

In the 1980s, aramid fibres brought a first advance, followed some years later by polyethylene, polyester and carbon. These fairly inelastic materials give sails a similar degree of tensile stiffness to an aeroplane wing, giving them optimum airflow lift force. Their excellent deformation-resistance means that these fibres are also used to provide guaranteed long life to some rigging ropes.

Taking things a step further, the sailmaker North Sails developed in the 1990s a new system for manufacturing moulded sails. They are made using a mould on which is applied a first polyester film on which is then laid a carbon fibre, polyethylene or polyester yarn following a custom configuration for the characteristics wanted. These fibres form the sail structure. A second polyester film is laid on, and the whole thing is heat cured to consolidate and unify the sail. This technique produces a sail 30% lighter than a traditional sail, while the absence of seams and its slightly curved shape give it a perfect aerodynamic profile for high-performance sailing.

Taking things a step further, the sailmaker North Sails developed in the 1990s a new system for manufacturing moulded sails. They are made using a mould on which is applied a first polyester film on which is then laid a carbon fibre, polyethylene or polyester yarn following a custom configuration for the characteristics wanted. These fibres form the sail structure. A second polyester film is laid on, and the whole thing is heat cured to consolidate and unify the sail. This technique produces a sail 30% lighter than a traditional sail, while the absence of seams and its slightly curved shape give it a perfect aerodynamic profile for high-performance sailing.