Zero Energy Buildings: Opportunity for Plastics

Environmental Protection Can Also Offer Social Benefits

Most people would love to live in a low cost, yet environmentally friendly house. Foyer Rémois, a French welfare housing association, made this dream come true. A recent project, called The Clearing (‘la Clairière’, in French) due end of 2009, consists of 13 social housing flats (2 to 5 bedrooms), 4 of which are specially adapted for the needs of disabled people.

The Association wanted to respect sustainable development in all its aspects: environmental, obviously, economic (by building large scale zero energy houses) and social, since the zero energy concepts reduce costs for the tenants.

Zero energy buildings

A passive house is a building in which a comfortable interior climate can be maintained without active heating and cooling systems. The house heats and cools itself, hence ‘passive’. For European passive construction, prerequisite to this capability is an annual heating requirement that is less than 15 kWh/(m²/year), fixed as a standard parameter. Furthermore, the combined primary energy consumption of living area of a European passive house may not exceed 120 kWh/ (m²/year) for heat, hot water and household electricity. To achieve this, the building has to use natural energy sources and special bioclimatic architecture in order to minimise energy usage.

Fresh air

Thermal insulation is a key element and the shape of the building is also important.

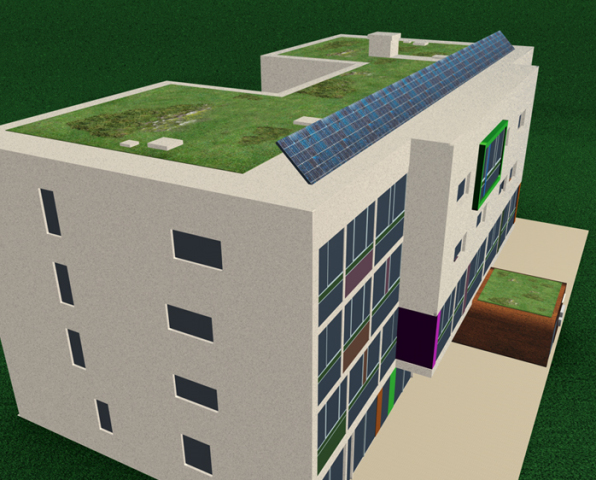

The design of The Clearing adds to energy efficiency.

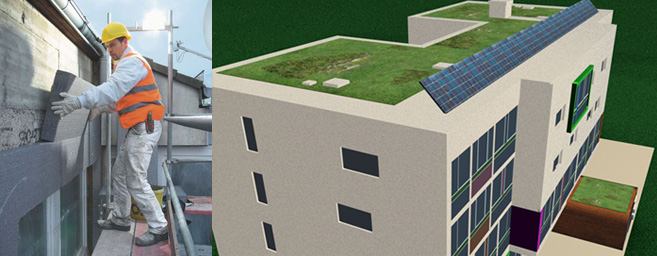

This is helped by 30 cm thick plastics insulation.

The architects wanted an efficient building in pleasant environment.

They did it: air circulation is optimized by a double flow ventilation system which uses the heat of the outgoing air to warm up the air from outside by way of a heat exchanger.

But the real innovation is the use of a totally natural heating system using the specifics of the architecture, known in French as bioclimatism.

Thermal insulation is a key element and the shape of the building is also important.

The design of The Clearing adds to energy efficiency.

This is helped by 30 cm thick plastics insulation.

The architects wanted an efficient building in pleasant environment.

They did it: air circulation is optimized by a double flow ventilation system which uses the heat of the outgoing air to warm up the air from outside by way of a heat exchanger.

But the real innovation is the use of a totally natural heating system using the specifics of the architecture, known in French as bioclimatism.

Bioclimatism: a Big Word for Common Sense

Some might assume this involves complex technology but the reality is simple. In order to take the maximum advantage of the sun, the building has a North/South orientation.

Each flat has been conceived in such a way that the heat from the sun benefits from large south-facing windows, whilst those on the north side are small to minimise energy loss.

On the roof, which is covered by vegetation, are photovoltaic panels, partly made from plastic. These allow energy to be produced on-site.

Lastly, a ‘Canadian well’ optimizes geothermal heating through internal pipes that maintain a constant temperature of 14°C throughout the year.

Some might assume this involves complex technology but the reality is simple. In order to take the maximum advantage of the sun, the building has a North/South orientation.

Each flat has been conceived in such a way that the heat from the sun benefits from large south-facing windows, whilst those on the north side are small to minimise energy loss.

On the roof, which is covered by vegetation, are photovoltaic panels, partly made from plastic. These allow energy to be produced on-site.

Lastly, a ‘Canadian well’ optimizes geothermal heating through internal pipes that maintain a constant temperature of 14°C throughout the year.

Plastics in buildings = energy efficiency

To ensure real energy efficiency demand to decrease energy consumption and greenhouse gas emissions. This places real challenges for house builders – both financial and environmental. Sometimes, they might have to also consider the views of public opinion about the technologies used. Only those involved in house design might know about the real benefits that plastics can offer in both monetary and sustainable areas. But The Clearing is a good example of this principle in practice. One amazing insulation product is Neopor®, which add to the environmental performance of the building. Not only does it insulate, but since it is also enriched with a dehumidifying agent and with infra red reflectors, it cuts down on heat losses. When a building is insulated with Neopor® yearly heat losses are reduced by 40%. And, that cuts the heating expenses of the tenants by 40%. Now, when would you like to move in?

To ensure real energy efficiency demand to decrease energy consumption and greenhouse gas emissions. This places real challenges for house builders – both financial and environmental. Sometimes, they might have to also consider the views of public opinion about the technologies used. Only those involved in house design might know about the real benefits that plastics can offer in both monetary and sustainable areas. But The Clearing is a good example of this principle in practice. One amazing insulation product is Neopor®, which add to the environmental performance of the building. Not only does it insulate, but since it is also enriched with a dehumidifying agent and with infra red reflectors, it cuts down on heat losses. When a building is insulated with Neopor® yearly heat losses are reduced by 40%. And, that cuts the heating expenses of the tenants by 40%. Now, when would you like to move in?

Ozzano: the Italian Passive and Stylish House.

The ‘passive house’ development at Ozzano Emilia near Bologna in Italy has been designed and realised by the Studio Arkit of Bologna. It was supported and developed by the Centro di Informazione sul PVC (the Italian association of the PVC industry) and AIPE (the Italian association of the EPS producers), The aim of the project was to develop an architectural approach based on two main concepts: energy saving (how to achieve energy saving and ‘passive house’, evaluating bioclimatic and architectural performance criteria; and to select affordable materials with a low environmental footprint, based on scientific data). This approach has resulted in a building that will save more than 90% in terms of energy consumption compared to an equivalent sized Italian building constructed using traditional techniques. The Ozzano Project includes five separate family houses and an Experimental Didactic Centre. The buildings and their performance will be monitored for five years in order to check the compliance with the requirements and if necessary modify them to be able to meet the required performance targets.

Sustainability from First to Last;

Ozzano saves energy and takes into account the environmental footprint of the materials and applications used as a fundamental principle of the design.

The project follows specific requirements in terms of ‘passive house’ classification, comfort (acoustic insulation, lighting quality, indoor safety criteria), static certification, architectonical barriers, safety systems, costs verification, recyclability and environmental impact (CO2).

Ozzano saves energy and takes into account the environmental footprint of the materials and applications used as a fundamental principle of the design.

The project follows specific requirements in terms of ‘passive house’ classification, comfort (acoustic insulation, lighting quality, indoor safety criteria), static certification, architectonical barriers, safety systems, costs verification, recyclability and environmental impact (CO2).

The choice of materials for this purpose is also critical: the materials thus must show a favourable LCA (Life Cycle Assessment) for each application, such as EPS and PVC for hyper-insulation and windows in order to guarantee optimal thermal performance, use of PVC piping systems for fluid and light transportation, EPS components for roofing, walls, and flooring insulation.

Affordable To Be Sustainable

A new building approach like that embodied by the Ozzano Emilia ‘passive house’ has the exploration of new processes, new methodologies, new use of materials and elements at a core goal of the project, whilst finding materials and simple technologies that anyone can afford.

This means building on conceptual innovation, energy efficiency and resource saving, but with costs of realisation that are comparable to traditional buildings; and with the potential for significant savings in terms of running costs.

In passive houses plastics in general and more specifically PVC and EPS are used for a variety of applications, all of which add to the building’s sustainability.

In the framework of the Ozzano project, PVC has been evaluated and chosen thanks to its favourable environmental performance (supported by LCA studies), cost-effectiveness, recyclability and high level technical properties, (durability, easy installation and maintenance, fire resistance and insulating characteristics). In the case of ‘la Clairière’, EPS was the insulating star.

A new building approach like that embodied by the Ozzano Emilia ‘passive house’ has the exploration of new processes, new methodologies, new use of materials and elements at a core goal of the project, whilst finding materials and simple technologies that anyone can afford.

This means building on conceptual innovation, energy efficiency and resource saving, but with costs of realisation that are comparable to traditional buildings; and with the potential for significant savings in terms of running costs.

In passive houses plastics in general and more specifically PVC and EPS are used for a variety of applications, all of which add to the building’s sustainability.

In the framework of the Ozzano project, PVC has been evaluated and chosen thanks to its favourable environmental performance (supported by LCA studies), cost-effectiveness, recyclability and high level technical properties, (durability, easy installation and maintenance, fire resistance and insulating characteristics). In the case of ‘la Clairière’, EPS was the insulating star.

Cats Have multiple Lives, so do Plastics

Plastics only “borrow” oil to constitute their raw material. Then, at the end of their first useful life, they can be recycled, sometimes repeatedly, to make new products and ultimately, the energy embodied in the polymer can be recovered. Plastics are definitely active in making houses become passive!