A battle on all fronts

A salutary struggle

It is a well-known fact that in a hospital environment nosocomial infections can wreak havoc. A figure to send a chill down your spine: irrespective of the material on an untreated surface, the quantities of germs double, on average, every twenty minutes.

It is therefore easier to understand the usefulness of these highly technical plastics, mainly in the health and food sectors where action to combat bacteria is clearly an issue.

It was there that the first applications saw the light of day. As ...icing on the cake, this technology also acts on odours since these are often due to the proliferation of germs.

In hospitals, they are everywhere !

There is no formal obligation to use products made of antibacterial materials in a hospital environment. Yet they are gradually becoming more and more essential in tenders for the replacement of equipment.

There is no formal obligation to use products made of antibacterial materials in a hospital environment. Yet they are gradually becoming more and more essential in tenders for the replacement of equipment.

Antibacterial polymers also have the advantage of not being much more expensive: the extra cost is around 10%.

The list of equipment is a long one: floor coverings, trolleys, footwear for staff, soap dispensers, curtains, door handles, beds, medical treatment chairs, etc. There are even dedicated vacuum cleaners for clean rooms such as operating suites where antibacterial plastic filters turn simple vacuuming into a disinfection process.

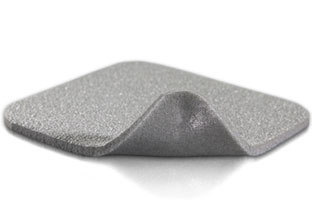

Bandages and plasters

For health care professionals and for patients above all, dealing with open wounds is of major importance. The healing process must be as quick as possible, with minimum pain.

For health care professionals and for patients above all, dealing with open wounds is of major importance. The healing process must be as quick as possible, with minimum pain.

High quality materials are constantly being developed to meet these, sometimes highly complex, requirements for infected wounds or those at risk of infection.

For instance, there are now innovative plasters combining silver salt, absorbent polyurethane foam and silicone-based adhesives. As a result, pathogenic germs are inhibited through the release of silver ions and the plaster does not stick to the wound and can be removed easily and painlessly.

Highly protected foods

In the food sector, antibacterial plastics are present in the form of transparent films for the packaging of fresh products such as meat, fruit and vegetables. Here too the term “killer” is very appropriate since this film captures and kills 99.9% of bacteria, including the infamous Escherichia coli.

Research is also moving ahead in this field. New polymers are beginning to emerge with the special feature of becoming active in the confirmed presence of bacteria.

This latest generation of packaging incorporates microcapsules which monitor the release of antibacterial agents only when the bacterium comes into contact with the plastic packaging.

Also a plus in cosmetics

Whilst the added health value of germicidal plastics in the medical and food sectors no longer needs demonstrating, it is also of interest to other industries such as the cosmetics industry.

Whilst the added health value of germicidal plastics in the medical and food sectors no longer needs demonstrating, it is also of interest to other industries such as the cosmetics industry.

Lipstick tubes, for example, are designed with antibacterial plastics. The American company DuPont has also developed Taklon®, a polyester fibre. Soft and supple, this fibre perfectly imitates boar bristles and can replace them to advantage in the manufacture of hairbrushes and makeup brushes as it can incorporate antibacterial agents.

Public hygiene everywhere

Among the great families of plastics are styrenic polymers (including polystyrene in particular). These polymers are prized by industrialists for their numerous features such as water-resistance, thermal and electrical insulation properties, rigidity, and a good solidity/weight ratio which makes their transport economical and facilitates production and recycling.

Among the great families of plastics are styrenic polymers (including polystyrene in particular). These polymers are prized by industrialists for their numerous features such as water-resistance, thermal and electrical insulation properties, rigidity, and a good solidity/weight ratio which makes their transport economical and facilitates production and recycling.

In 2008, the German chemical company BASF incorporated silver compounds in this plastic which give their surface germicidal properties. This range is called Luran® S BX 13042. The combination of this antimicrobial property with the qualities of this polymer opens up interesting applications, especially in health fields for objects such as hand driers, soap dispensers and even entire public toilet blocks.

Manufacturers have been specialising in the design of external peripherals for public places. In particular, they make keyboards and computer mice whose plastic parts are treated with an antibacterial additive for hospitals, schools and places with many users. As an additional benefit, the cases enclosing these components are hermetic and can therefore be washed in water.

For its part the Austrian group Gabriel-Chemie proposes antimicrobial polymers for optimal utilisation of polyolefins: polyethylene, polypropylene, etc. These plastics are all around us every day since they are used in the manufacture of objects as varied as air-conditioning equipment, toothbrushes, toilet seats, razors and mobile telephones. This polymer is also used in outdoor equipment such as water pipes to inhibit the formation of biofilms, in other words bacterial and fungal coatings, and thus prolong the life of the pipes.

There are also outlets in the textile industry

Whereas the first applications that come to mind involve medicine and food, other more original applications concern textiles.

Whereas the first applications that come to mind involve medicine and food, other more original applications concern textiles.

In the 80s, fabrics were covered with antimicrobial agents in order to prevent germs from wearing them out too quickly. Then, with the development and widespread introduction of technical sports clothing, the chemical industry found a way of permanently coating polymer fibres with silver iodide, thus making the material active.

Whilst today these applications still mostly concern only technical sports clothing, we are willing to bet that they are going to develop even more: in car seats and mattress coverings, for example, or to be used as filling for motorbike helmets.

The darling of sportspersons

It is no secret to anyone that the phenomenon of sweating is linked to the development of bacteria giving off a repulsive smell. To overcome this, microfibres of nylon or polyester have been treated with silver iodide. This led to the appearance of Polygiène®, a fabric perfectly suited for sporting activities due to its stretching, breathing and, of course, antibacterial qualities. This is also the type of finish found on many sports mats and judo tatamis.

It is no secret to anyone that the phenomenon of sweating is linked to the development of bacteria giving off a repulsive smell. To overcome this, microfibres of nylon or polyester have been treated with silver iodide. This led to the appearance of Polygiène®, a fabric perfectly suited for sporting activities due to its stretching, breathing and, of course, antibacterial qualities. This is also the type of finish found on many sports mats and judo tatamis.

MORE INFORMATION

www.gabriel-chemie.com

www.molnlycke.com/fr

www.unotron.com