Plastics have some front!

Rejuvenating buildings

The buildings in most European countries are older than their occupants. Nine out of ten are over 35 years old and up to a third were built before the last war. All are therefore showing their age, especially on the facades. And very often, a simple facelift will just not do.

Apart from the aesthetic aspect, proper refacing work today aims to protect the building as a whole against all forms of external attack: water, noise, heat and cold, pollution...An impossible task without a wide range of polymers!

No-one could seriously consider permanent repairs to cracked brickwork without cellulose ethers and synthetic latex industrial mortars, for example, multilayer plastic coatings, often reinforced with a composite membrane, are usually the ultimate riposte to water ingress.

The drawback, however, is that while very effective, such weatherproofing can encourage condensation. Not a problem! Arkéma, for example, has a solution for replacing the plastic in microporous membranes with a breathable polymer film similar to that used in surgical clothing.

The drawback, however, is that while very effective, such weatherproofing can encourage condensation. Not a problem! Arkéma, for example, has a solution for replacing the plastic in microporous membranes with a breathable polymer film similar to that used in surgical clothing.

Another way of tackling both cold and damp is to clad façades with an external wall insulation system (EWIS) comprising a thermally-insulated expanded polystyrene cladding covered with reinforced or plain plastic ‘rendering’.

This currently very fashionable process is likely to develop further through thinner, but equally high-performance, coatings with an embedded polymeric phase change material whose microcapsules embedded in the insulation coating will store or release heat depending on the weather conditions -The perfect way to keep warm in winter and stay cool in summer.

Plastics give a window on the world

Seen from inside, a facade is primarily a light well - and a part of the building that is judged by the number and quality of its windows! Therefore the importance of a robust seal between window and wall.

Seen from inside, a facade is primarily a light well - and a part of the building that is judged by the number and quality of its windows! Therefore the importance of a robust seal between window and wall.

Here, efficiency is no longer just about adhesive strength, but also very much about sealing and insulation. This is exactly where polyurethanes and silicones come into the picture. Sealing and filling is what they do...and windows are where they do it.

In France alone, for example, 12 million windows are fitted each year, in addition to the existing 250 million, not to mention conservatories, and the sophisticated facades of commercial buildings...That adds up to more than 15 million m2 of insulating glazing.

Year in, year out, all this takes millions of kilometres of foam and sealants made from these polymers. Some, for sealing double glazing filled with inert insulating gas (air or argon), others to make the interior joinery and window casing joints for windows which, in over 60% of cases, are of PVC.

Safety polymers for structural glazing

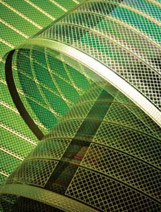

The trend in most commercial buildings is for transparency as an emblem of high-tech credentials. This has led to the development of new techniques like structural glazing to obtain an all-glass facade.

The trend in most commercial buildings is for transparency as an emblem of high-tech credentials. This has led to the development of new techniques like structural glazing to obtain an all-glass facade.

The glazing is bonded using polymer sealants which have to cope with wind forces, the weight of the glass and even its deformation inside the frame while maintaining their adhesive properties. Because exposing the glass to building movements is the one thing that must not happen.

This kind of high performance structural bonding has developed over the past fifteen years as a result of chemical industry advances in epoxy resins, polyurethanes, polysulfides and silicones.

Bright ideas for glass

Polymers are not only essential for the manufacture of double-glazed windows, they are now found in the composition of glass itself. The aim is to develop "smart glass" with new functions.

Polymers are not only essential for the manufacture of double-glazed windows, they are now found in the composition of glass itself. The aim is to develop "smart glass" with new functions.

Saint-Gobain, for instance, has through the inclusion of polyvinyl butyral (PVB) acoustic films in laminated glass, developed what it calls "silence" glazing.

Another recent innovation is electrochromic glazing, manufactured using switchable technology, that reduce the brightness and heat generated by the greenhouse effect in summer. An offshoot of rear-view mirror manufacture, the technique consists in sandwiching an electroactive polymer film containing liquid crystal suspended particles that darken in sunshine between the layers of glass.

In the same vein, progress with thin plastic films still has many discoveries to yield, most recently that of the young Dutch start-up Peer+, a spin-off of the Technical University of Eindhoven, which has developed Smart Energy Glass - even more sophisticated glazing whose polymer layer switches light intensity between three modes...and uses it to generate electricity.

Architecture inspires chemistry

One of the most amazing molecules recently discovered by chemists is fullerene - so-named in tribute to the celebrated American architect Richard Buckminster Fuller, designer of the football-shaped geodesic dome. By a quirk of history, this molecule named for an architect is set fair for a bright future in building.

One of the most amazing molecules recently discovered by chemists is fullerene - so-named in tribute to the celebrated American architect Richard Buckminster Fuller, designer of the football-shaped geodesic dome. By a quirk of history, this molecule named for an architect is set fair for a bright future in building.

By tweaking the "nano-footballs" of fullerene in their test tubes, Piétrick Hudhomme and his colleagues at the University of Angers in France have developed a new type of photovoltaic coating as an alternative to existing heavy and bulky silicon-based panels.

They have done it using polymer films (polyacetylene or polythiophene) combined with fullerene derivatives. Their approach is particularly promising for photovoltaic conversion in that it should enable large areas to be covered with very little material. Who knows, the future may even see the polymer film integrated into wall facings.