The future of plastic solar panels

And then there was electricity

Transforming light into electricity is not a modern concept. As early as in the 1830s, the physicist Antoine Becquerel had already observed that elements that conduct electricity could produce an electric current when they were lit up. However, we had to wait until the end of the 19th century and the emergence of nuclear physics to explain this phenomenon. When we take a semiconducting material and expose it to light, we can see that the photons, the elementary particles of light, tear apart the electrons, leaving a hole. And as nature abhors a vacuum, these electrons desperately look for a free space, thus producing an electric current. What happens in a photovoltaic cell is elegantly simple.

Silicon: a technology that is too expensive …

Photovoltaic cells are now mostly made of silicon. Silica is an abundant raw material and therefore cheap. However, making photovoltaic cells from this material is very expensive, as it requires a lot of energy. This manufacturing process is often compared with microprocessors. Their production cost is in the region of €4 per watt produced. Studies show that, consequently, silicon-based photovoltaic cells will only begin to pay for themselves after several years. This is so, even on the basis of 15% efficiency (i.e. on the basis that the conversion rate of solar radiation to energy is 15%).

Photovoltaic cells are now mostly made of silicon. Silica is an abundant raw material and therefore cheap. However, making photovoltaic cells from this material is very expensive, as it requires a lot of energy. This manufacturing process is often compared with microprocessors. Their production cost is in the region of €4 per watt produced. Studies show that, consequently, silicon-based photovoltaic cells will only begin to pay for themselves after several years. This is so, even on the basis of 15% efficiency (i.e. on the basis that the conversion rate of solar radiation to energy is 15%).

... And soon to become outdated?

We have quite a paradox here: silicon photovoltaic cells produce electricity by means of a clean and free energy source (the sun) but their production requires a large amount of energy from hydrocarbons. It’s like squaring the circle!

We have quite a paradox here: silicon photovoltaic cells produce electricity by means of a clean and free energy source (the sun) but their production requires a large amount of energy from hydrocarbons. It’s like squaring the circle!

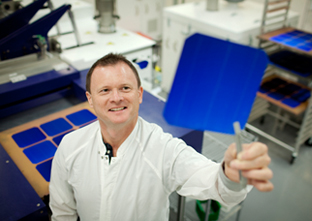

Organic cells could be a solution to the problem. This innovative technology is still at the experimental stage, but some prototypes are already leaving the laboratory and enabling us to visualise the revolution they will bring about in the years, or even months, to come.

100 % plastic cells

Organic cells are, in fact, and quite simply, plastic cells. The major advantage of the polymers that will be included in the composition of future solar panels is the cost of manufacture which are much cheaper than related mineral materials. That is not the only advantage of this new technology, however, as these new panels will be much lighter and particularly more flexible and will therefore be suitable for any type of surface. When will they be available on the market? The technology is developing quickly, but there are still a few problems. The first relates to the efficiency, around 5%, which could be improved on. The second concerns the still low resistance of these cells to UV. It is a reasonable wager that this technology will be available quite soon, because its future applications are already feeding the dreams of many designers who imagine it on their office blocks or even car roofs.

I’m printing my solar panel

Solar ink has well and truly arrived. It will very soon be possible to imagine printing your own solar panel with a small office printer. Canadian chemists have actually developed a photovoltaic ink that can be applied to a flexible, fine and light plastic film. This ink can be used virtually anywhere to transform objects, furnishings or other surfaces into organic solar batteries. It can be printed onto fabrics, plastic films or glass to transform curtains, clothing, parasols and even windows into photovoltaic batteries. Researchers have created a new family of polymers to achieve this result: polycarbazoles, a group of carbon, hydrogen, nitrogen and sulphur atoms. The result is striking; this ink is photosensitive, conducts electricity, is resistant to water, heat and bad weather and enables the production of cells with an efficiency of 8%. Telephone chargers using this technology should appear very soon. These cells will be a true revolution that should bring about significant changes to our habits and our way of life.

Solar ink has well and truly arrived. It will very soon be possible to imagine printing your own solar panel with a small office printer. Canadian chemists have actually developed a photovoltaic ink that can be applied to a flexible, fine and light plastic film. This ink can be used virtually anywhere to transform objects, furnishings or other surfaces into organic solar batteries. It can be printed onto fabrics, plastic films or glass to transform curtains, clothing, parasols and even windows into photovoltaic batteries. Researchers have created a new family of polymers to achieve this result: polycarbazoles, a group of carbon, hydrogen, nitrogen and sulphur atoms. The result is striking; this ink is photosensitive, conducts electricity, is resistant to water, heat and bad weather and enables the production of cells with an efficiency of 8%. Telephone chargers using this technology should appear very soon. These cells will be a true revolution that should bring about significant changes to our habits and our way of life.