A new point of view through plastics

Hard-wearing organic lenses

One of the advantages of using polymers in the production of optical instruments lies mainly in the techniques, such as moulding, which enable organic lenses to be mass-produced and at lower costs than those of machined mineral lenses.

In the eyewear industry, for instance, organic lenses have come out on top thanks to the use of polymers whose transparency is suitably close to that of optical lenses.

Polymethyl methacrylate (PMMA) may be the best-known thermoplastic but it certainly is not the most widely used, mainly due to its tendency to lose volume during the polymerization process.

Polycarbonate, valued for its light weight and impact resistance, does not suffer from the same drawback. However, for ophthalmic applications, it requires a protective scratch-proof coating.

One of the most widely-used polymer in eyewear manufacturing is a thermosetting resin called polyurethane, better known as CR39: it offers a good compromise between strength and optical properties.

One of the most widely-used polymer in eyewear manufacturing is a thermosetting resin called polyurethane, better known as CR39: it offers a good compromise between strength and optical properties.

Pittsburgh Plate Glass, the company which developed it in the 1940s, recently developed a polymer which can compete with polycarbonate in the field of impact resistance.

Originally developed as a "visual armour" for military helicopters, Trivex is a nitrogen-enriched polyurethane derivative. The reaction achieved during the process of polymerisation reinforces the polymer's structure at the nanoscale, alternating hard and soft areas. This results in a material with superior optical properties and which is also exceptionally robust and lightweight.

Polymer lenses for miniature auto-focus

In photography, focusing consists in moving the lens according to the distance to the subject. This is done automatically on autofocus lenses thanks to a small Voice Coil Motor (VCM).

In photography, focusing consists in moving the lens according to the distance to the subject. This is done automatically on autofocus lenses thanks to a small Voice Coil Motor (VCM).

The autofocus lens consumes too much energy on tablets and smartphones, so it has been replaced with a fixed small-aperture lens. Although it is sufficient for outdoor photography, its low-light levels make sharp indoor photography difficult.

For the millions of mobile devices lacking autofocus, but fitted with increasingly powerful sensors (up to 16 megapixels), the answer to this problem probably lies in the new generation of adaptive lenses.

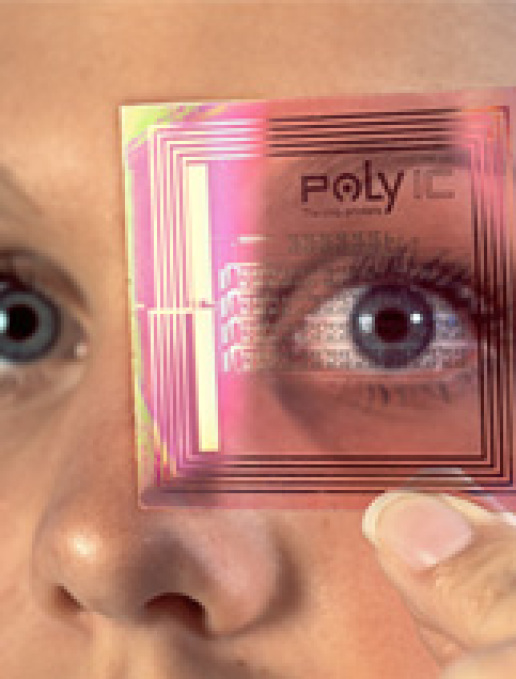

The adaptive lens developed by PoLight, a recent start-up born from a partnership between Sintef, one of Scandinavia's main research centres, and the École polytechnique fédérale in Lausanne, mimics the lens of the human eye.

This miniature "sandwich-type” lens, measuring 3mm across, is able to capture more light by varying the curvature of a high-transparency polymer lens protected by a flexible glass. By deforming itself under the effect of impulses sent by a piezoelectric film, the lens is able to focus in less than a millisecond!

This almost instantaneous reaction time means that PoLight is able to promise, in addition to an autofocus capability for all devices, a new mode called "all-in-focus" which takes a succession of ultra-fast pictures to make a pin-sharp picture in every respect.

Capturing light from all angles

In order to produce adaptive lenses, researchers from the National Optical Institute, the Institute of Polymer Chemistry and Technologies, and the University of Naples Federico II took a different tack by combining liquid crystals with a polymer.

Sometimes crystalline, and sometimes fluid, these materials are organised in a manner which is characteristic of both the liquid and solid states. This feature is widely-exploited in the manufactures of electronic devices as commonplace as watches or digital alarm clocks and has been utilised in an innovative way by Italian researchers.

They were able to fragment the liquid crystals into microscopic drops which can then be assembled into larger drops that can be calibrated according to the desired size. By depositing these droplets onto a substrate coated with an organomineral polymer, dimethicone (PDMS), they obtained varifocal microlenses.

The behaviour of these lenses opens up the way for unexpected developments in the field of photography: for instance, to focus on objects at different depths of field or in the field of photovoltaics, by manufacturing spherical lenses able to capture sunlight from any, and all, angles.