Humanoids – your robot pal

Robots – all in the family

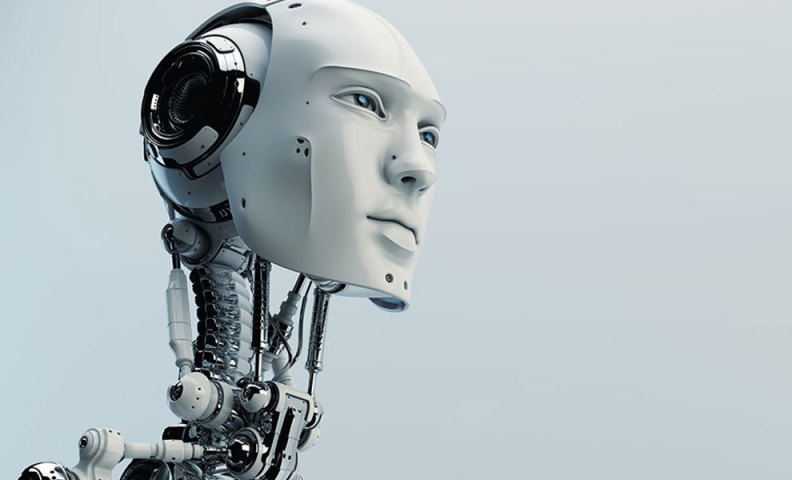

Humanoids are robots based on human morphology. So far, they have been in the collective imagination only through sci-fi films with some, like Star Wars’ C3PO, becoming stars in their own right. Now, the dream is almost reality. Many laboratories are working on projects of varying outlandishness to develop robots that can interact with their environment. Not to mention pure intelligence. The aim is not only to give them more fluid movements, but also a face capable of human expressions. Pure fantasy?

Plastics to make the perfect human

Can you build an artificial muscle? There’s no easy answer, because a robot is of course just a machine made up of different computer-programmed servo motors. But, the real world, that of humans, does not square with the mathematical world of computer programs. As yet, robots are still quite rigid and frequently overbalance. So, many laboratories are testing out more sensitive new motors and new materials that should enable robots to adapt to their environment – moving from hard to soft ground, for example. This is what the Growbot programme is doing by studying the applications of a polymer that hardens or softens with temperature to mimic the characteristics of muscle, thus enabling the robot to adapt to differences in the type of ground.

Elastic-driven

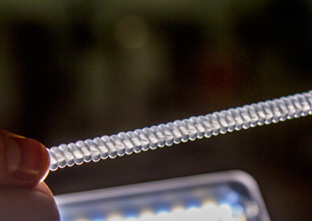

Following this principle, the Ecce robot has been equipped with muscles designed with elastic polymers to give it some flexibility. In humans, for instance, twelve muscles are required to activate the shoulder. Ecce has ten. This means that Ecce’s movements are not jerky but appear more natural. In another big breakthrough in the robotics world, Singaporean scientists have created muscles composed of electrically stimulated polymer macromolecules which can lift up to 80 times their weight and stretch five times their length when lifting a load. Even so, the researchers are hoping to move towards a stretch of 10 times their length and a lifting ability 500 times that of human muscles. Using polymer also has the advantage of being able to store energy, enabling motion-actuated self-powered robots to be designed.

More astonishing still, an international team from the University of Texas has managed to make artificial muscles out of ordinary fishing nets by twisting them into a sort of spring made of polymer fibres. Heating the spring causes it to contract up to 50%, compared to 20% for natural muscles, thereby enabling it to lift loads a hundred times greater than a human muscle of the same length and weight. The clincher: this plastic muscle is much cheaper (US$ 5 per kg) than the shape memory metal alloys available on the market. These artificial muscles could therefore be used to make prostheses and exoskeletons much lighter and above all, less cumbersome than servo motors and hydraulic-powered models.

Artificial tactile skin

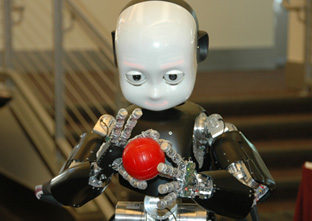

Having developed a form of artificial brain, a consortium of twenty European universities headed by a team from the University of Genoa, are working hard to give their creation, the iCub robot, the sense of touch. Such will be its sensitivity that it will be able to distinguish a real egg from a stone egg and so avoid crushing it. Its hands, arms and torso have been covered with a skin comprising over 2200 tactile elements, dubbed taxels, interconnected via a network of microcontrollers. This electronic skin is designed as layers of elastomer. Granted that this skin still nowhere near equals the human tactile system and lacks pain receptors, but the scientists believe it to be a big step forward that should fulfil all its potential.

Happy robot, sad robot

Forgetting that it’s a machine and feeling that it has emotional responses...That is yet another challenge that robot creators want to meet. And they are not far off with Joey Chaos, a robot created by Hanson Robotics in the United States. It doesn’t move, and is only a plastic torso and head. But the really big surprise is when it starts talking, the movement of each muscle of a human face is so perfectly reproduced. Its skin is made of a spongy polymer, light and flexible enough, to be controlled by small actuators. The head is fitted with motion detection systems and voice recognition sensors that send signals to an external computer which in turn controls the actuators to produce facial and vocal expressions. The illusion is...unnerving.

Why are so many teams of scientists working on projects like these around the world? Why go all out to mimic the human body? The ultimate answer to these questions lies mainly in what purpose these robots will serve. Whatever else, they will not be biddable slaves! Where they should come in useful, by contrast, is in helping sufferers of cognitive diseases like Alzheimer's. These robots would be the perfect companion, unfailingly patient and caring, helping to improve communication and social interaction, and reducing behavioural problems.