Robots and polymers: a deal set in steel!

Polymers: wrapped-up robots

The science fiction films of the last century, some of which were set in our current time, featured intelligent robots which, due to a lack of imagination, had two arms and a head, some being more benevolent than others. They were able to communicate with humans through a synthetic voice, quite a modern concept at the time. A different time? Not necessarily, as evidenced by the famous C3PO of the Star Wars saga who continues to delight fans around the world. So, what is the situation actually like today? Some may be unhappy with it, but the reality of the matter is quite different. Just like the smartphone whose development few had foreseen, robots have evolved along paths that no one imagined 30 years ago. Since the end of the 20th century, researchers have put aside the idea of reproducing the human anatomy as a whole and have instead focused their research on creating robots whose function is to perform tasks that humans are not capable of performing. The best-known example of this focus is the robotic arm, which has been around for many years and has proved its worth in the industrial sector in particular. It is able to weld with precision, grasp fragile objects with great care, assemble all types of parts, and even perform surgical operations. Similarly, robots have entered our homes and now suck up dust, mow the lawn, clean swimming pools, cook up good food and more.

Although the “slave robot” remains a utopian fantasy, robots are nevertheless becoming increasingly common, helping us out with many tasks. |

Robots show solidarity with humans

How can we fail to mention the Covid-19 epidemic and the containment periods that it caused in many countries? Robots equipped with a connected digital tablet have enabled elderly people confined in retirement homes to stay connected with their relatives. Other robots were tasked with disinfecting supermarket shelves.

Because they are unaffected by biological viruses, robots have been very useful during the Covid outbreak. |

Similarly, some delivery services have not been disrupted thanks in large part to the robots able to pick up the goods from the racks, thus avoiding warehouse workers from numbers of potentially harmful interactions. In addition to being intelligent, these robots are so efficient because they were designed using polymer materials that combine strength and above all lightness, the key to ever greater autonomy. |

This is one thing that almost all these robots have in common. Whether polycarbonate or ABS, which are particularly resistant materials for the shells, and elastomers selected for their elasticity, robot manufacturers use a wide range of plastic materials when designing their robots.

However, the role and contribution of plastics is not limited to design or protection functions alone. Many research centres have understood that it is by developing new polymers that they will be able to provide robots with totally new functions. While some research is still at the experimental stage, other projects have already been completed and the results are surprising, again worthy of the best works of science fiction.

Please hide that drone from me

When it comes to robots, drones are the focus of much research. They have become so important in the military and intelligence world that they now benefit from large funding budgets. Thus, as is the case with their human-piloted cousins, parts made of composite materials based on carbon and epoxy resins feature heavily in their design. These lighter materials reduce the drones’ energy consumption and increase their autonomy. However, there is nothing revolutionary about this perfectly mastered technology which is becoming more and more commonplace in the world of aeronautics and more generally in the world of transport.

|

However, one of the current challenges is to make drones invisible, or at least undetectable by radar. Although stealth aircraft have been around since the 1970s, their stealth is relative. It relies solely on the shape of the cockpit, which is very angular in order to disperse radar waves in all directions. This works only to a certain extent because, inevitably, at some point a wave will be sent back to the radar. Flexible materials capable of absorbing waves do exist, but they are not rigid enough to be used in building a plane or a drone. |

Stealth aircraft are nothing new. However, polymers have revolutionised the field, and drones in particular. |

Yet, it appears that a Russian aircraft manufacturer may just have succeeded in achieving that objective. To do this, it developed a new material based on various secret fibres and polymer resins. All we know is that the rigidity of the material enables it to be used to build a drone and that this new composite absorbs almost all waves. To make it even less easily detectable, the manufacturer gave it the shape and size of an owl. In flight, without binoculars, it is almost impossible to differentiate it from the real bird. This spy drone is equipped with cameras. Still according to the manufacturer, its indiscernibility to radar waves and its resemblance to a simple owl allow it to fly very low without being detected and to take very precise pictures.

|

The very same principle was also adopted by a Franco-British consortium specialising in the design of underwater drones. Once again, we will not be privy to much more information about the fibres and resins used. This new drone’s mission is to locate submarines without being detected. While the composite materials developed for its construction help to reduce its mass and thus increase its autonomy, above all they make it indiscernible to sonar waves since they are capable of absorbing all noise and vibrations. |

Underwater drones, covered in composite materials, can also be made invisible. |

According to its designers, this drone will not be limited to military missions. It may also be of humanitarian interest. In the event of a tsunami, for example, it could detect underwater obstacles and thus pave the way for relief vessels.

Polymers better than Harry Potter

To close the chapter on stealth, many universities have spent the past decade working on ways of making any object properly invisible. To do this, they focused their research on metamaterials, composite materials with novel electromagnetic properties not found in any natural material. These materials are in fact capable of exceeding the diffraction limit of light and can therefore make the objects with which they are built invisible. Thus, physicists believe that within a few years they will be able to design a true "cloak of invisibility" that would force light rays to bypass the object and then resume their normal course. With such a cloak, it would be as if the rays were passing through the object, making it completely invisible to any observer. All that remains to be done to move from theory to practice is to design the material – not an easy endeavour as all the work is carried out at the nanoscopic scale. Metamaterials are essentially made up of fine metallic patterns (whose thickness can approach a dozen nanometres, or ten billionths of a metre) deposited on the surface of a substrate that is transparent to electromagnetic waves. The latter is made of glass where rigidity is desired, or sheets of polymers where, on the contrary, flexibility is sought. It is the latter technology that interests invisibility enthusiasts because, in the long term, it would be possible to produce sheets of the material measuring several metres long, which could then be applied like wallpaper to the object to be made invisible. Drones could be the first to benefit from this technology.

Polymers have ants in their pants

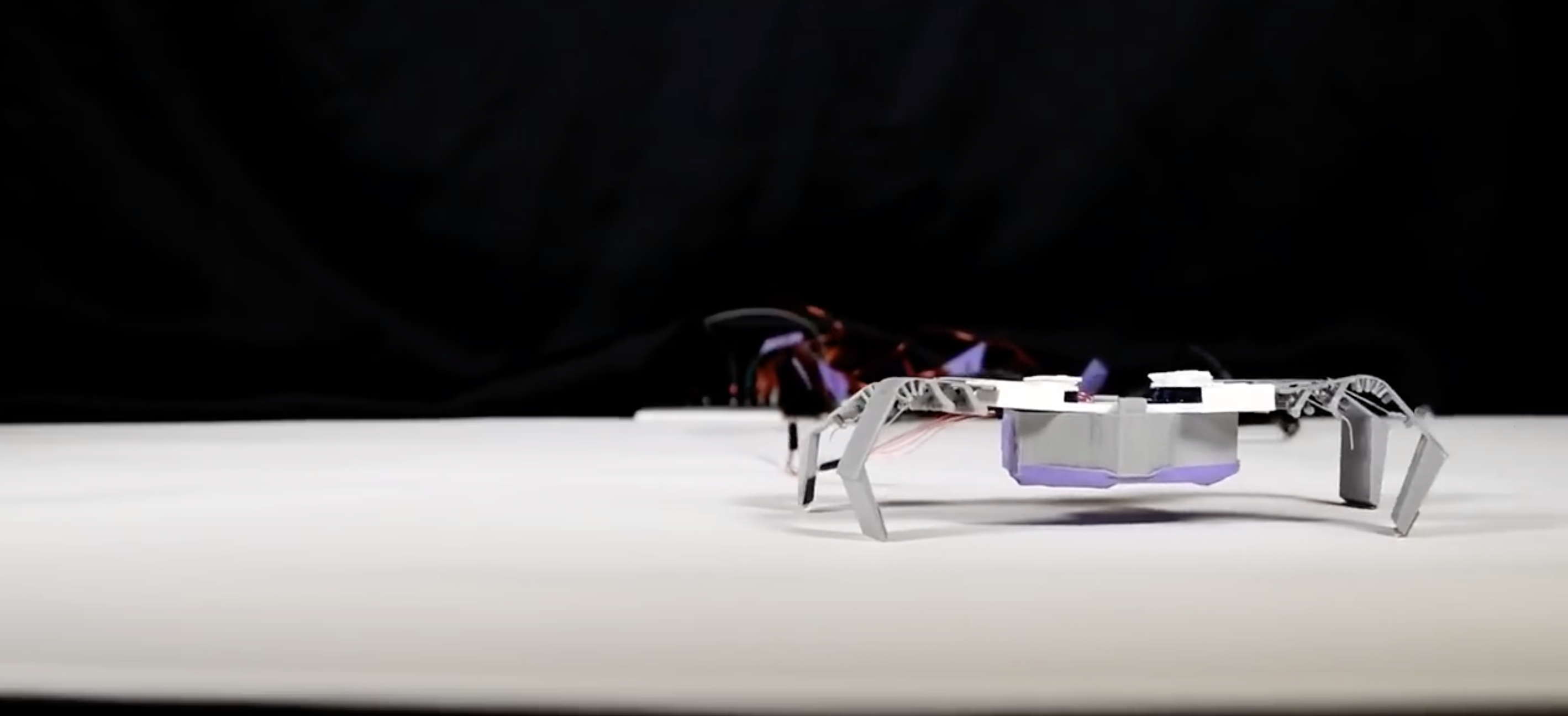

It seems almost trivial to announce that a team from the University of San Diego in the United States recently succeeded in printing small robots that look like insects. Yet this feat could eventually revolutionize the world of robotics and many other fields. Researchers at the university developed a process for printing insect robots in 3D in a single piece, which they have named "flexoskeleton" (flexible exoskeleton). In fact, these little robots are made of different rigid plastics, such as polycarbonate, 3D-printed directly onto very thin and flexible layers of another polymer. Therefore, they are rigid and flexible at the same time, like an insect whose shell is rigid enough to protect it and flexible enough to be properly articulated and mobile. Flexoskeletons could also be used for espionage, since it would be fairly simple and above all quick to reproduce a swarm of fake insects and equip them with miniature cameras.

Polycarbonate for rigidity, soft polymers for flexibility – a fruitful combination used to reproduce the unique properties of insects’ shells. |

Particularly inspired by cockroaches, other Californian researchers are also working on robot insects. Measuring about the size of a cockroach, their robot is particularly solid since it can support a weight of 60kg, i.e. 1 million times its own weight.

Polyvinylidene fluoride (PVDF) has made it possible to create a cockroach robot that, like the insect, is able to find its way even under a pile of rubble. |

It consists of a flat structure made from a polymer called PVDF (polyvinylidene fluoride) which contracts or expands according to the intensity of an electric current flowing through it. Its curved shape allows it to move forward with the contractions and expansions. Because of its mobility and small size, which allows it to crawl into very small spaces, it could be useful in searching for survivors after an earthquake. Researchers plan to eventually equip it with a sensor that can detect CO2 exhaled by survivors. |

Plastics remake the Terminator

Difficult to forget the robot in Terminator 2 which could change its shape to suit its needs. Fascinating! Thirty years later, what was one of the first digital special effects in the history of cinema is about to become reality. We owe this discovery to a team from Binghamton University in the United States who designed an alloy based on bismuth, indium and tin which has the particularity of passing to the liquid state at 62°. However, upon reaching the liquid state, the metal will begin to spread if nothing holds it back. The team created a flexible framework to confine the alloy, opting for a flexible polymer in the family of elastomers. The metal was then vacuum-cast directly onto the structure. Like in the film of the 1990s, the result is fascinating.

|

By simply heating and then cooling this assembly, which here takes the shape of a hand, it automatically returns to its original shape after being deformed or even crushed. In a few years' time, researchers plan to use this material to design certain parts of space robots, such as antennas, which will be able to return to their original shape if they are crushed or deformed following a rock fall or collision, for example. |

Liquid metal and polymers, the winning combination for creating a new material with true shape memory. |

Polymers suited and booted

On the lighter side of things, the paths that have been explored in the field of robotics have also revealed some amusing and even amazing discoveries. Even fashion designers have been seduced by robots! That is the case, at least, for designer Ying Gao who recently unveiled a collection of robotic clothes. Obviously, this is not a case of dressing robots, but on the contrary of creating more or less autonomous clothes. Called "Flowing water, standing time", the robotic garment is based on electronic components and parts made of silicone, glass and PVDF, a particularly resistant thermoplastic fluoropolymer.

The “robot phenomenon” has even taken hold of the fashion world. This dress made of PVDF, silicone and glass reacts to light. |

Combining the three materials makes it possible to create garments that can react to the colours of their environment and move accordingly. "Depending on the colours of their immediate environment, they are both liquid and chameleon-like, modulating their appearance according to the slow rhythm of the changing reflections of their surroundings" explained the designer. There is nothing magical about the principle, which is based on light sensors connected to a series of magnets and small mechanisms woven into the silicone parts. |

Although the effect is only visual, it may open up a new path for designers, that of the robot garment: a red light to tie my shoes and a green light to untie them!